The Alberta Energy Regulator (AER) is responsible for the oversight and regulation of energy resource development in Alberta. AER’s responsibilities include activities related to oil, bitumen, natural gas, and coal development. AER provides a framework for companies to follow through several directives to ensure safe, efficient, and environmentally responsible development of Alberta’s natural resources. One of these directives is: Directive 017 – Measurement Requirements for Oil and Gas Operations

Here is a link to all the directives (https://www.aer.ca/regulating-development/rules-and-directives/directives)

Directive 017 – What is it?

This directive provides the requirements relating to measurement points used for the accounting and reporting of oil and gas operations. Directive 017 intends to provide guidance for the following activities:

- what, where and how volumes are to be measured or estimated

- what accounting calculations should be used and when

- what volumes must be reported

- what data must be kept for audits

The last point refers specifically to measurement schematics, which is section 1.9 in the directive. You can read more about Directive 017 here…

Section 1.9 – Measurement Schematics

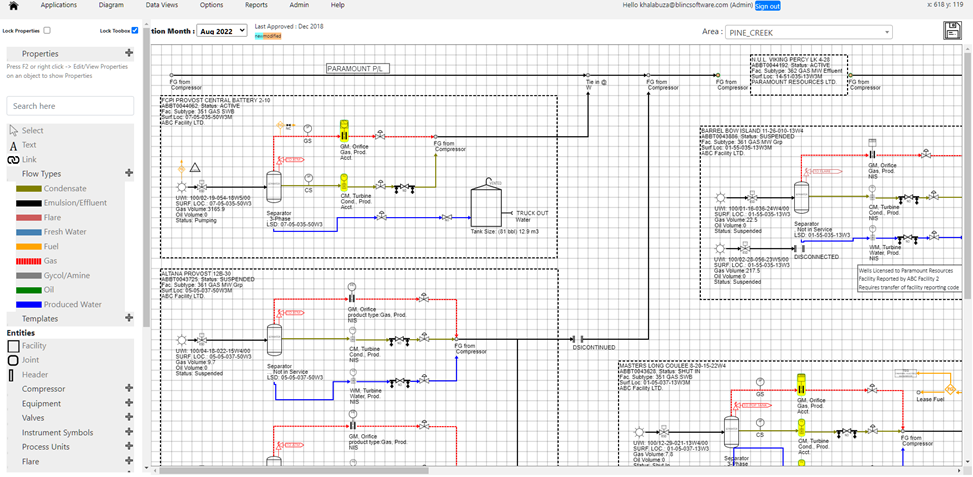

Measurement schematics show the flow and layout of a facility, in an easy-to-understand diagram. These schematics are required by Directive 017 to ensure accuracy of measurement, accounting and reporting for oil and gas facilities. Measurement schematics are used to give a visual representation of a facilities field data capture system, as well as for verification purposes. They can also be used by different departments (accounting, operations, engineering) within a company for collaboration purposes. Oil and Gas operators must keep an up-to-date copy of these schematics to provide upon request. As well, they must update the measurement schematic annually or when a change is made at the field level and verify revisions.

What are Measurement Schematics?

Measurement schematics are not the same process flow diagrams or process and instrumentation diagrams (P&ID’s). Measurement schematics are more general and must include the following, as outlined by Directive 017[1]:

- Facility name, facility licensee name, and operator name if different

- LSL of surface facility and UWI, including downhole location if different

- Facility boundaries between each reporting facility with associated Petrinex codes and subtypes. For larger facilities, an optional field flow diagram may be used to show facility delineation.

- Flow lines with flow direction that move fluids in and out of the facility and those that connect the essential process equipment within the facility, including recycle lines and bypasses to measurement equipment. Identify if oil is tied into a gas system.

- Flow split or diversion points (headers) with LSL if not on a well or facility lease site

- Process equipment that changes the state or composition of the fluid(s) within the facility, such as separators, treaters, dehydrators, compressors, sweetening and refrigeration units, etc.

- Measurement points and storage tanks or vessels that are used for estimating, accounting, or reporting purposes, including − type of measurement (meter, weight scale, or gauge); − type of instrumentation (charts, EFM, or readouts); − types of meters, if applicable; and − testing or proving taps required by the AER.

- Fuel, flare, or vent take-off points—default to estimated if meter not shown

- Energy source (gas, propane, electricity) used for equipment if not measured or estimated as part of total site fuel

- Permanent flare points

- Freshwater sources, such as lakes and rivers

- UWIs and LSLs are to be in a delimited format, such as 100/16-06-056-02W5/02 and 16-06-056-02W5, respectively.

- Multiple facilities can be on the same page and a typical schematic may be used for wells or facilities with the same measurement configuration.

If you would like to learn more about the specific requirements for measurement schematics, please read section 1.9.1 of Directive 017 here…

[1] 1-32 Directive 017: Measurement Requirements for Oil and Gas Operations (March 2022)

SchematicPro and Measurement Schematics

SchematicPro is an easy to use, smart measurement schematic drawing tool that helps your company remain compliant with Directive 017. SchematicPro takes care of all the requirements set out in Directive 017 and allows you to focus on other parts of your business.

Drawing

SchematicPro makes drawing easy and quick… with no experience required! The drag and drop interface allows you to create professional schematics quickly, without complicated drawing tools such as AutoCAD.

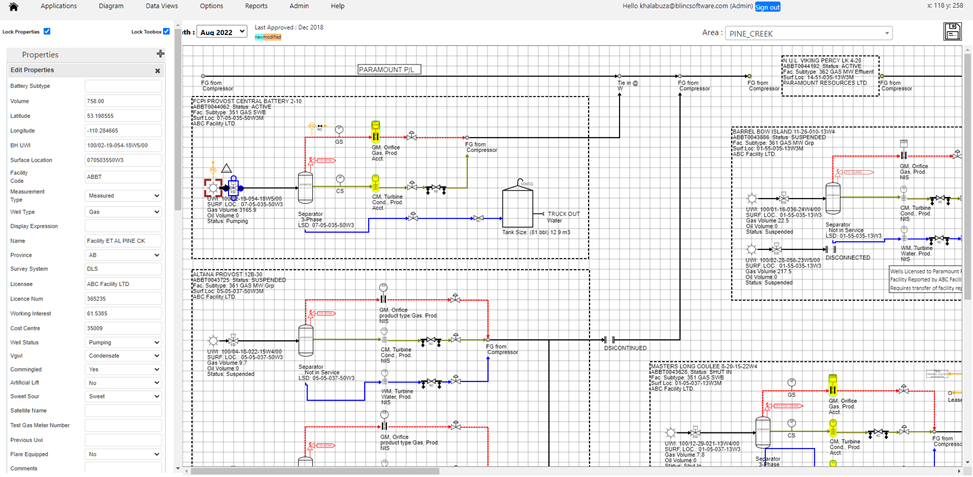

Item Properties

Items such as wells, vessels, and facilities are all required to display specific information in accordance with Directive 017. SchematicPro comes pre-configured with all required properties, allowing you to quickly input your information for each item. You are also able to add custom properties as per your company requirements. Custom display expressions allow you show these properties on the schematic, the way you want!

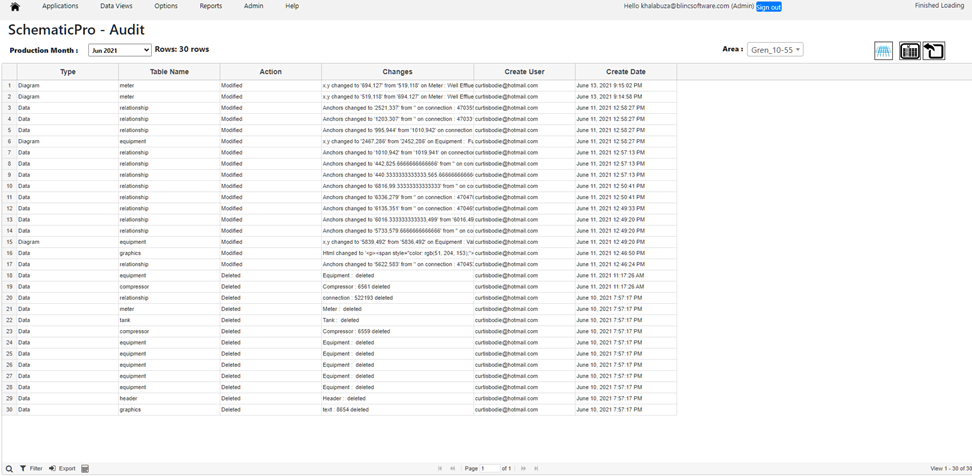

Audit

Directive 017 requires operators to keep previous versions for a minimum of 18 months. SchematicPro goes above and beyond this requirement and keeps a full history of all changes made to your schematics. This allows your company to see when and why changes were made.

Notifications

SchematicPro can notify you when your schematic approval is overdue. Alerts and notifications help you remain in compliance by letting you know when changes have been made or… when they have not! Schematics can be easily approved or unapproved for each month by specified users.

Petrinex

SchematicPro can import your wells and facilities directly from Petrinex to save time. Use pre-defined or custom templates to import your facilities into new or existing schematics. This will ensure you remain compliant with Directive 017 requirements while auto-populating property data which you would otherwise have to do manually.

Summary

SchematicPro can help your company become and remain compliant with AER Directive 017. It allows you to quickly create and maintain your measurements schematics without the need for expensive and complicated software. Add, update, and audit your schematics with a single program. Receive notifications when you need them for your schematics. Connect with Petrinex and other data sources to create “smart schematics” for your operations.

If you would like to learn more about SchematicPro feel free to reach out with any questions or request a demo today